Sustainability plays a critical role in fabric production today. The conventional methods of manufacturing fabrics, including poly elastane, often lead to significant environmental impacts. For instance, approximately 200 liters of water are consumed for every kilogram of fabric processed. Additionally, harmful chemicals and greenhouse gas emissions pose serious threats to the environment.

Poly elastane fabric, known for its flexibility and durability, holds a prominent position in the apparel industry. As consumer awareness about these environmental issues rises, the demand for eco-friendly poly elastane manufacturing practices increases. Brands are now exploring sustainable alternatives to reduce their ecological footprint.

Key Takeaways

- Sustainability is essential in fabric production to reduce environmental impacts.

- Poly elastane fabric combines polyester and elastane, offering flexibility and durability.

- Traditional poly elastane production consumes significant resources and emits harmful pollutants.

- Innovative sustainable yarns like ROICA V550 and ROICA EF use recycled materials to minimize waste.

- Sustainable practices can lower carbon footprints and reduce water usage by up to 90%.

- Consumers can support sustainability by choosing eco-friendly brands and participating in recycling programs.

- Caring for poly elastane garments properly can extend their lifespan and reduce environmental impact.

- Transparency in sourcing and production helps consumers identify truly sustainable brands.

Understanding Poly Elastane Fabric

Poly elastane fabric, often referred to as spandex, combines two primary components: polyester and elastane. This unique blend contributes to its exceptional properties, making it a popular choice in the apparel industry.

Composition of Poly Elastane

Role of Polyester

Polyester serves as the backbone of poly elastane fabric. It provides strength and durability, ensuring that garments withstand wear and tear. The initial stage of production involves mixing di-phenylmethane di-iso-cyanide monomer with micro polyester. This combination creates a robust structure that enhances the fabric’s longevity.

Role of Elastane

Elastane, primarily made from polyurethane, is a long-chain polymer known as a polyether-polyurea copolymer. The production process includes the reaction of macro glycol with diisocyanate monomer, resulting in polymers that are processed into elastane fibers. The rigid segments formed by aromatic isocyanates provide strength and stability, while the flexible segments, containing polyols such as polyether, contribute to the fabric’s elasticity.

Performance Characteristics

Poly elastane fabric boasts several performance characteristics that make it suitable for both activewear and everyday clothing.

Durability and Strength

- Exceptional Strength: Synthetic fabrics like spandex are engineered for remarkable strength and durability, making them ideal for activewear.

- Shape Retention: Poly elastane can stretch up to seven times its original length and return to its original form after stretching, ensuring a good fit.

- Resistance to Wear: The fabric resists wear, sweat, and sun exposure, enhancing its longevity compared to natural fibers like cotton and wool, which may lack the same level of durability.

Moisture Management and Comfort

- Moisture-Wicking: Poly elastane pulls sweat away from the skin and helps it evaporate quickly, keeping the wearer comfortable during physical activities.

- Breathability: The fabric allows moisture to escape, ensuring that the wearer remains cool and dry.

- Flexibility: This fabric allows for freedom of movement, making it ideal for both activewear and everyday clothing.

The unique chemical structure of poly elastane fabric sets it apart from other stretch fabrics in the apparel industry. Unlike polyester and nylon, which typically require blending with elastane to achieve elasticity, poly elastane’s composition allows it to stretch significantly while maintaining its shape.

Current Practices in Poly Elastane Production

The production of poly elastane fabric has evolved over the years, yet traditional manufacturing methods still dominate the industry. These conventional practices raise significant environmental concerns and consume vast resources.

Traditional Manufacturing Methods

Environmental Concerns

Traditional poly elastane production relies heavily on petroleum, contributing to fossil fuel depletion. This process also involves high energy consumption, which leads to increased carbon emissions. Additionally, manufacturers often use harmful chemical treatments, such as Dimethylformamide (DMF), which pose health risks to workers and the surrounding community. The non-biodegradable nature of poly elastane means it can persist in the environment for hundreds of years, complicating recycling efforts and disrupting mechanical recycling processes.

Key environmental concerns associated with traditional poly elastane production include:

- Petroleum use: Contributes to fossil fuel depletion.

- High energy consumption: Leads to increased carbon emissions.

- Harmful chemical treatments: Chemicals like DMF pose health risks.

- Non-biodegradability: Fabric persists in the environment for centuries.

- Complicated recycling efforts: Disrupts mechanical recycling processes.

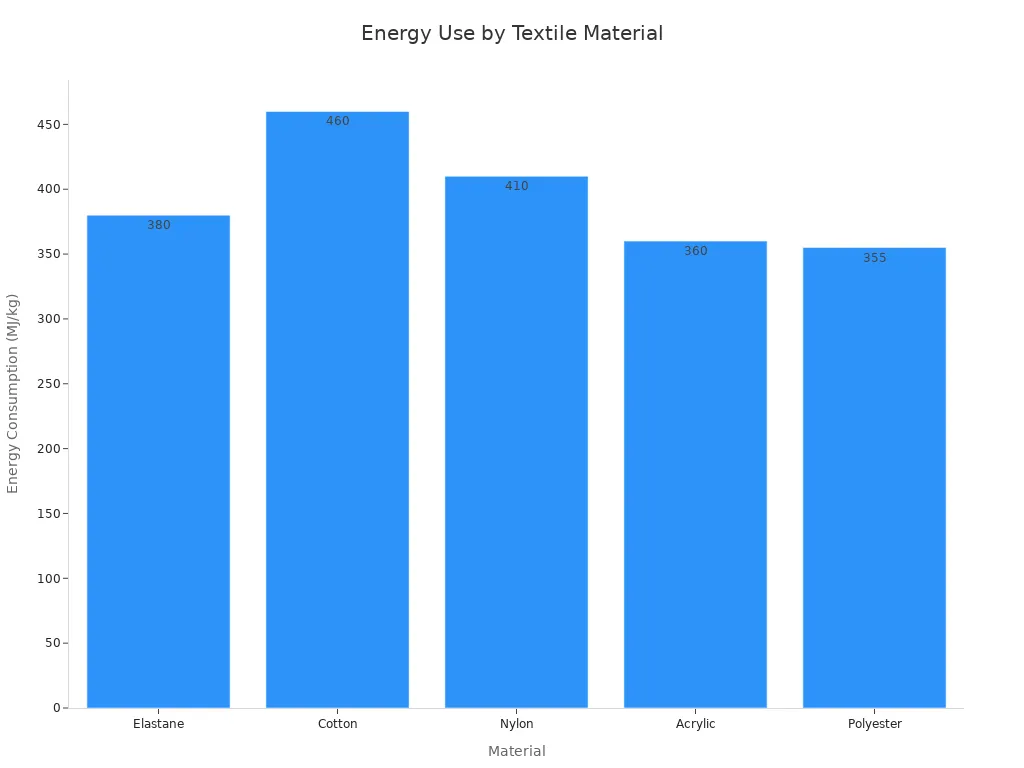

Resource Consumption

The resource consumption in conventional poly elastane manufacturing is substantial. The following table illustrates the energy consumption associated with various materials used in fabric production:

| Material | Energy Consumption (MJ/kg) |

|---|---|

| Elastane | 380 |

| Cotton | 460 |

| Nylon | 410 |

| Acrylic | 360 |

| Polyester | 355 |

Innovations in Production

In response to the environmental challenges posed by traditional methods, the industry has begun to embrace innovative production techniques. These advancements aim to reduce the ecological footprint of poly elastane manufacturing.

ROICA V550 Sustainable Yarn

ROICA V550 is a sustainable yarn produced from recycled materials. This innovative yarn significantly reduces textile waste and is biodegradable, making it a more environmentally friendly option compared to traditional yarns that rely on non-renewable resources.

ROICA EF Recycled Yarn

Similarly, ROICA EF recycled yarn offers a sustainable alternative by utilizing post-consumer waste. This approach not only minimizes waste but also conserves resources by reducing the need for virgin materials. Sustainable yarns like ROICA V550 and ROICA EF provide substantial environmental benefits, including:

- Production from recycled materials: Reduces textile waste.

- Biodegradability: Minimizes long-term environmental impact.

- Lower reliance on non-renewable resources: Supports sustainable practices.

These innovations represent a significant shift towards more sustainable practices in poly elastane fabric production, aligning with the growing consumer demand for eco-friendly options.

Benefits of Sustainable Poly Elastane Fabric

Sustainable poly elastane fabric offers numerous benefits that extend beyond individual garments. These advantages encompass both environmental impacts and consumer experiences, making them essential considerations in today’s textile industry.

Environmental Advantages

Reduced Carbon Footprint

Sustainable practices in poly elastane production significantly lower carbon emissions. For instance, recycling polyester can reduce energy consumption by 59% and lower CO₂ emissions by 32% compared to using virgin polyester. This reduction plays a crucial role in combating climate change and promoting a healthier planet.

Moreover, some manufacturers have adopted closed-loop dyeing systems, achieving a remarkable 40% reduction in water consumption over two years. Such initiatives demonstrate a commitment to sustainability while minimizing the environmental impact of fabric production.

Lower Water Usage

Water conservation is another critical advantage of sustainable poly elastane fabric. By utilizing recycled materials, manufacturers can reduce water usage by up to 90% compared to traditional methods. Green elastic materials, made from recycled or organic fibers, provide similar stretch and durability as conventional options while being environmentally friendly. This shift not only conserves vital water resources but also supports sustainable practices in the textile industry.

Consumer Benefits

Sustainable poly elastane fabric not only benefits the environment but also enhances the consumer experience.

Eco-Friendly Choices

Consumers increasingly seek eco-friendly options in their apparel. Sustainable blends combine the desirable properties of elastane with eco-friendly fibers, resulting in responsible textiles. The manufacturing processes for these fabrics minimize waste and resource consumption, aligning with the values of environmentally conscious shoppers.

Enhanced Product Quality

Sustainable poly elastane products often meet high standards for quality and performance. The durability and elasticity of elastane allow garments to maintain their shape over time, even after numerous washes. Sustainable alternatives, such as Tencel and recycled polyester, provide similar stretch qualities while being more environmentally friendly.

The following table summarizes the benefits associated with choosing sustainable poly elastane apparel:

| Benefit Type | Description |

|---|---|

| Eco-Friendly Attributes | Sustainable blends combine elastane’s properties with eco-friendly fibers for responsible textiles. |

| Eco-Friendly Manufacturing | Environmentally responsible methods minimize waste and resource consumption. |

| Commitment to Quality and Sustainability | Ensures products meet high standards for quality and environmental responsibility. |

Case Studies of Sustainable Brands

Brand A: Leading the Way

Sustainable Practices Implemented

Brand A has established itself as a leader in sustainable poly elastane fabric production. The company has implemented several eco-friendly practices that significantly reduce its environmental impact. For instance, Brand A utilizes renewable energy sources in its manufacturing processes. This shift has led to a substantial decrease in carbon emissions. Additionally, the brand has adopted a closed-loop water system, which recycles water used during production. This system minimizes water waste and conserves vital resources.

Brand A also prioritizes transparency in its supply chain. The company collaborates with suppliers who adhere to strict environmental standards. By ensuring that all materials are sourced responsibly, Brand A enhances its commitment to sustainability. These practices not only benefit the environment but also resonate with consumers who value ethical production.

Impact on Production and Sales

The sustainable initiatives of Brand A have positively influenced its production efficiency and sales figures. By reducing energy consumption and waste, the company has lowered operational costs. This efficiency allows Brand A to offer competitive pricing while maintaining high-quality products.

Furthermore, consumer response has been overwhelmingly positive. Many shoppers prefer brands that demonstrate a commitment to sustainability. As a result, Brand A has seen a significant increase in customer loyalty and market share. The brand’s reputation for eco-friendly practices has attracted a growing segment of environmentally conscious consumers.

Brand B: Innovative Approaches

Use of Recycled Materials

Brand B has taken innovative approaches to sustainability by incorporating recycled materials into its poly elastane fabric production. The brand sources post-consumer waste, transforming it into high-quality fibers. This practice not only reduces textile waste but also conserves resources. By utilizing recycled materials, Brand B significantly lowers its environmental footprint.

The brand’s commitment to recycling resonates with eco-conscious consumers. Many shoppers are more likely to trust and support companies that actively work to reduce their environmental impact. In fact, nearly 90% of consumers express a preference for brands that demonstrate environmental progress. This commitment enhances customer trust and loyalty, positioning Brand B favorably in a competitive market.

Community Engagement and Education

Brand B also emphasizes community engagement and education. The company conducts workshops and campaigns to raise awareness about sustainable practices. These initiatives encourage consumers to make informed choices about their clothing. By fostering a sense of community, Brand B strengthens its brand identity and builds lasting relationships with its customers.

Through these efforts, Brand B not only promotes sustainability but also empowers consumers to participate in the movement. This approach creates a positive feedback loop, where informed consumers drive demand for sustainable products.

Best Practices for Consumers

Caring for poly elastane apparel is essential for maximizing sustainability and ensuring longevity. Consumers can adopt several best practices to maintain their garments effectively.

Caring for Poly Elastane Apparel

Washing and Maintenance Tips

To preserve the quality of poly elastane clothing, consumers should follow these washing and maintenance tips:

- Always adhere to the care instructions provided on the garment label.

- Use cold water for washing to minimize energy consumption.

- Avoid fabric softeners, as they can break down the fibers over time.

- Air dry garments whenever possible to reduce energy use and prevent heat damage.

By implementing these practices, consumers can extend the life of their poly elastane apparel while minimizing environmental impact.

Extending the Life of Your Garments

Extending the lifespan of clothing contributes to sustainability. Here are some effective strategies:

- Repair instead of replace: When garments show signs of wear, consider mending them rather than discarding them.

- Check for durability: Before purchasing, assess the garment’s quality to ensure it can withstand regular use.

- Be mindful of elastane’s environmental impact: Understanding the implications of elastane can help consumers make informed choices.

These actions not only benefit the environment but also promote a more sustainable fashion culture.

Making Sustainable Choices

Consumers play a crucial role in promoting sustainability in the poly elastane industry. By making informed choices, they can support eco-friendly practices.

Identifying Eco-Friendly Brands

When searching for sustainable poly elastane brands, consumers should consider the following criteria:

| Criteria | Description |

|---|---|

| Sourcing | Where and how a fabric is sourced is crucial for determining its sustainability. |

| Environmental Impact | The environmental impact during production is a key factor in assessing sustainability. |

| Certifications | Look for certifications like Oeko-Tex and Cradle to Cradle that ensure safe and sustainable practices. |

| Chemical Safety | Avoid brands that use harsh chemicals, pesticides, or carcinogenic materials in their production. |

| Natural vs. Man-made Textiles | Prefer natural fabrics over man-made ones to reduce environmental issues associated with elastane. |

By evaluating these factors, consumers can identify brands that prioritize sustainability.

Supporting Sustainable Practices

Consumers can actively support sustainable practices in the poly elastane apparel industry through various actions:

- Participate in take-back schemes offered by brands to ensure proper disposal of apparel.

- Support companies with extended producer responsibility (EPR) initiatives that manage product disposal.

- Engage in garment repair programs to extend the life of clothing.

- Utilize platforms like Patagonia’s Worn Wear for buying and trading secondhand clothing.

These actions foster a culture of sustainability and encourage brands to adopt eco-friendly practices.

Sustainability in poly elastane production is crucial for addressing environmental concerns. The reliance on petroleum-based materials, resource-intensive manufacturing processes, and pollution from synthetic dyes highlight the need for change. The table below summarizes these key issues:

| Environmental Concern | Description |

|---|---|

| Reliance on petroleum-based materials | Elastane is primarily made from polyurethane, which is derived from non-renewable petroleum. |

| Resource-intensive manufacturing processes | The production of elastane requires significant energy and water, contributing to resource depletion. |

| Pollution and waste | The use of synthetic dyes leads to toxic waste that harms aquatic life and ecosystems. |

| Non-biodegradability | Elastane garments contribute to textile waste in landfills, as they do not decompose easily. |

Consumers can drive sustainable change by making informed choices. They should consider eco-labels and support brands that prioritize transparency. Key points include:

- Consumer choices can significantly influence sustainability in the poly elastane industry.

- Eco-label standards help consumers make better choices, driving demand for sustainable products.

- The slow fashion trend emphasizes the need for transparency to avoid greenwashing.

Brands must adopt eco-friendly practices, such as using ROICA™ V550 elastic and incorporating recycled materials. Together, these efforts can lead to a more sustainable future in the apparel industry.

FAQ

What is poly elastane fabric?

Poly elastane fabric is a blend of polyester and elastane. This combination provides exceptional flexibility, durability, and comfort, making it popular in activewear and everyday clothing.

Why is sustainability important in fabric production?

Sustainability in fabric production reduces environmental impacts, such as carbon emissions and resource depletion. It promotes eco-friendly practices that benefit both the planet and consumers.

How can consumers identify eco-friendly poly elastane brands?

Consumers should look for brands that prioritize sustainable sourcing, use recycled materials, and possess certifications like Oeko-Tex. Transparency in production processes also indicates a commitment to sustainability.

What are the benefits of sustainable poly elastane fabric?

Sustainable poly elastane fabric offers reduced carbon footprints, lower water usage, and enhanced product quality. These benefits contribute to a healthier environment and better consumer experiences.

How can I care for my poly elastane garments?

To care for poly elastane garments, wash in cold water, avoid fabric softeners, and air dry when possible. Following care instructions helps extend the life of the clothing.

What innovations are being made in poly elastane production?

Innovations include the development of sustainable yarns like ROICA V550 and ROICA EF, which utilize recycled materials. These advancements aim to reduce waste and environmental impact.

How does traditional poly elastane production harm the environment?

Traditional production relies on petroleum, consumes significant energy, and uses harmful chemicals. These practices contribute to pollution, resource depletion, and long-lasting textile waste.

What role do consumers play in promoting sustainability?

Consumers influence sustainability by choosing eco-friendly brands, participating in recycling programs, and supporting companies with responsible practices. Their choices drive demand for sustainable products in the market.